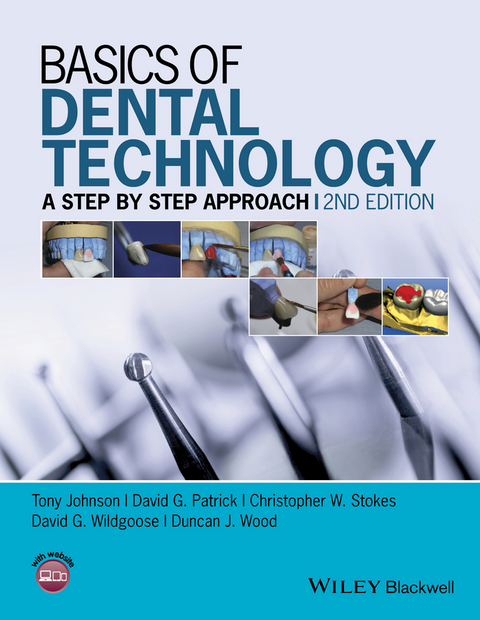

Basics of Dental Technology (eBook)

200 Seiten

Wiley (Verlag)

978-1-118-88622-9 (ISBN)

Now available in a second edition, Basics of Dental Technology is a complete reference for the current techniques and materials used in dental technology.

- Retains the accessible, task-based approach and step-by-step guidance of the first edition

- Features updates throughout, as well as a new chapter on digital dental technology and an interactive student website to support self-assessment

- Explains key competencies, concepts, instruments, and equipment, and also introduces more specialist techniques and procedures, such as denture prosthetics, fixed prosthodontics, orthodontic work, and maxillofacial technology

- Provides essential information for trainee dental technicians and students learning about dental technology, including study tips and strategies for working effectively within a dental team

Dr Tony Johnson is a Senior Lecturer in the Academic Unit of Restorative Dentistry and Head of the Dental Technology Unit at the School of Clinical Dentistry at the University of Sheffield, UK.

Dr David G. Patrick is a University Teacher in the Dental Technology Unit, Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University of Sheffield, UK.

Dr Christopher W. Stokes is a Senior University Teacher in the Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University of Sheffield, UK.

Mr David G. Wildgoose until his retirement in 2009 was a Dental Instructor in the Dental Technology Unit, Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University of Sheffield, UK.

Dr Duncan J. Wood is a Senior University Teacher in the Dental Technology Unit, Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University of Sheffield, UK.

Now available in a second edition, Basics of Dental Technology is a complete reference for the current techniques and materials used in dental technology. Retains the accessible, task-based approach and step-by-step guidance of the first edition Features updates throughout, as well as a new chapter on digital dental technology and an interactive student website to support self-assessment Explains key competencies, concepts, instruments, and equipment, and also introduces more specialist techniques and procedures, such as denture prosthetics, fixed prosthodontics and orthodontic work Provides essential information for trainee dental technicians and students learning about dental technology, including study tips and strategies for working effectively within a dental team

Dr Tony Johnson is Senior Lecturer in the Academic Unit of Restorative Dentistry and Head of the Dental Technology Unit at the School of Clinical Dentistry at the University of Sheffield, UK. Dr David G. Patrick is a University Teacher in the Dental Technology Unit, Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University of Sheffield, UK. Dr Christopher W. Stokes is Senior University Teacher in the Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University of Sheffield, UK. Mr David G. Wildgoose until his retirement in 2009 was a Dental Instructor in the Dental Technology Unit, Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University Sheffield, UK. Dr Duncan J. Wood is a Senior University Teacher in the Dental Technology Unit, Academic Unit of Restorative Dentistry at the School of Clinical Dentistry at the University of Sheffield, UK.

Chapter 1

INTRODUCTION

1.1 Introduction

This book has been designed for use in the dental laboratory as a guide for the novice dental technician. Described in the manner of a ‘cook book’, the procedures in this handbook have been designed to be followed step by step. Presented in sections ordered by specialty, each procedure has been completed in a dental laboratory, with photographs illustrating all the important steps of each procedure. The work shown in this book has not been edited or tweaked, but is presented as the instructions given in this book were followed, to ensure that the outcomes are achievable by anyone following the guides (perhaps with a little practice!).

1.2 How to use this book

This book is designed for the student of dental technology for use on the bench in the dental laboratory. The construction of many dental prostheses and appliances requires progression through a series of stages, often from impression through to the finished product. You can use this book to work through each procedure step by step.

The graphic at the beginning of the sections will help you to see where any given procedure fits into the production process. An example of this is shown on the right.

For each procedure you will find a brief introduction, a list of the tools and equipment required, guidance on working safely and an illustrated step-by-step basic procedure.

In addition, the hints and tips sections give techniques to expand or refine the process, and the extended information sections give an insight into the scientific and clinical aspects that can enhance your understanding of the topic.

1.3 Equipment and instruments

The equipment listed below is commonly found in a dental laboratory, and with which any technician should be familiar.

Plaster bowl, spatula and knife (Figure 1.3.1)

Common to all plaster rooms, these items are used for mixing, shaping and trimming plaster of Paris, Kaffir and die stone materials. Cleanliness of these items is important to prevent rapid setting of materials.

Wax knives and carvers

These instruments are commonly used in the laboratory for a number of procedures. You should purchase your own good-quality knives and carvers.

- Small wax knife: Most commonly used in the fabrication of crowns for placing and carving inlay wax. You may see technicians using two, a cold and a hot knife, to save time (Figure 1.3.2, instrument on the left).

- Large wax knife: Used for melting, placing and carving modelling wax in the production of dentures. Again, it is common to see two knives being used, a cold and a hot knife (Figure 1.3.2, instrument on the right).

- LeCron carver: This carver is popular for the carving of inlay wax in the production of crowns. It is used cold, but some techniques use it slightly warm, but not hot (Figure 1.3.3, instrument on the far right).

- Ash 5: This carver is used cold to shape modelling wax in the production of dentures (Figure 1.3.3, instrument in the centre).

- Hylin carver: This carver is popular for the carving of inlay wax in the production of crowns. It is used cold (Figure 1.3.3, instrument on the far left).

- PKT (PK Thomas): A set of instruments (examples of two shown) designed to aid the precise positioning of molten wax in the production of crowns (Figure 1.3.4).

Other hand instruments

- Ceramic brushes: Available in a range of sizes similarly to artists' brushes (Figure 1.3.5), with sizes from 0 to 20 with 0 being the smallest and 20 the largest. These brushes are made from sable and should be treated with care. A size 6 brush is popular for the placement of ceramics in the production of crowns. Smaller brushes are useful for staining, and a larger brush for condensing ceramic.

- Ceramic spatulas: These instruments (Figure 1.3.6) are used for mixing, placing and carving of ceramic powders. They are produced from a material that will not contaminate the ceramic with metal particles that may cause discoloration.

- Micromotors: Modern micromotors (Figure 1.3.7) are very advanced in terms of engineering, control and quality. They are powered by low voltage electricity and usually controlled via a foot or knee controller, allowing the speed to be set anywhere between 5000 and 40 000 rpm. The chuck is opened and closed by twisting the handpiece to secure or remove a bur.

Burs

There is a huge range of burs currently on the market and manufacturers devote several pages of their catalogues to them. Below is a brief outline of the main types.

- Tungsten carbide (TC): These are very popular burs used for many applications within the laboratory from trimming plaster to acrylic and metal. They are available in a large selection of shapes and sizes (Figure 1.3.8). The most useful are the plaster trimmers, flame-shaped for trimming acrylic and small round (often called rosehead) burs for accessing small areas.

- Steel burs: As above, but not as hard wearing (and cheaper).

- Stone burs: Abrasive stone burs are available in different grades, shapes, sizes and materials. The shapes range from cones to points to discs (Figure 1.3.9) and the different materials are indicated (often by colour) for different applications, that is, for the trimming and finishing of ceramics, acrylics or alloys.

- Diamond discs and burs: Increasingly popular over the past decade, these tools are used for the shaping of ceramics and composites. They are available in many shapes and sizes (Figure 1.3.10).

- Rubber abrasives for metals: These are available as wheels, cones or points and are used mainly in the finishing of metal surfaces (Figure 1.3.11).

- Abrasives for acrylics: The simplest is a mandrel that holds a small piece of sandpaper, but rubber-bonded abrasives are now popular (Figure 1.3.12).

- Brushes and mops: The main application of these is the polishing of metal surfaces in combination with wax-based polishing compounds (Figure 1.3.13).

Pliers and cutters

For orthodontic appliance manufacture (or for any other occasion where a wire may need to be bent or cut) the technician will have a selection of tools.

- Adams 65: Square-ended pliers used in the bending of orthodontic stainless steel wire (Figure 1.3.14).

- Adams 64: Square- and round-ended pliers used in the forming of springs and curves in orthodontic wires (Figure 1.3.15). (Sometimes referred to as ‘half-round’.)

- Maun cutters: Used for the cutting of orthodontic stainless steel wires (Figure 1.3.16).

- Parallel pliers: Used for firmly griping a variety of items (Figure 1.3.17).

Large laboratory equipment

Most laboratories will have most or all of the following (illustrations of some of the following equipment will appear later in the book).

- Model grinder: A bench-mounted, water-lubricated, tungsten carbide wheel used to grind plaster products (Figure 1.3.18).

- Polishing lathe: Used with brushes and pumice, or mops and polishing wax in the polishing of acrylics and alloys (Figure 1.3.19). Modern lathes have integrated dust extraction and lighting and have two speeds: 1500 or 3000 rpm. The polishing lathe can be fitted with a variety of brushes and mops, for example, a bristle brush for applying abrasive pumice to acrylics (Figure 1.3.20) or a cotton mop for polishing acrylics or alloys (Figure 1.3.21).

- Steam cleaner: Used extensively in the dental laboratory for cleaning models and restorations.

- Pressure bath: These use compressed air to keep self-curing acrylics under pressure during curing. They also have the facility to keep water warm to aid the process.

- Hydroflask: Used full of water for putting self-curing acrylic under pressure whilst curing, in the repair of dentures, for example (Figure 1.3.22).

- Vibrating table: Used during the mixing and pouring of plaster materials to help avoid air bubbles.

- Vacuum mixer: Essential in the production...

| Erscheint lt. Verlag | 6.8.2015 |

|---|---|

| Sprache | englisch |

| Themenwelt | Medizin / Pharmazie ► Allgemeines / Lexika |

| Medizin / Pharmazie ► Gesundheitsfachberufe | |

| Medizin / Pharmazie ► Zahnmedizin | |

| Schlagworte | Dental Technology & Materials Science • dentistry • Restaurative Zahnheilkunde • restorative dentistry • Zahnheilkunde • Zahnheilkunde / Technologie u. Materialwissenschaft • Zahnmedizin |

| ISBN-10 | 1-118-88622-4 / 1118886224 |

| ISBN-13 | 978-1-118-88622-9 / 9781118886229 |

| Haben Sie eine Frage zum Produkt? |

Größe: 37,5 MB

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich